- HOME>

- Special Contents>

- Project Story>

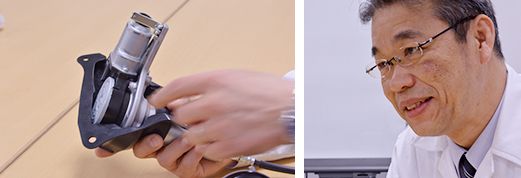

- Development of an electric front fork and rear cushion unit

Project Story

Aiming for quality and performance that outclass foreign products

While some overseas manufacturers are leaders in electrical suspensions, we decided to develop them because we foresaw even higher demand in the future. We’re newcomers here, and we wanted to offer something even better than traditional electrical suspensions. KYB is now the leader amongst all Japanese manufacturers. They already have competitive products on the market, so our development began by thoroughly examining their products. First we looked at performance, and then set our performance targets. Of course, producing products that outperform existing products is a problem, but our targets unequivocally had to be higher. There also are very few motorbikes, so from a cost perspective it would be difficult to create new products; our focus therefore was how we could modify existing products. The hardest part was the issue of the development schedule. As a newcomer, there was the idea that we had to get something out as quickly as possible, but we were starting from scratch, and it would take two years just to start mass production. It all came down to this extremely tight schedule. It’s difficult to balance basic development while doing mass production development when development schedules are tight. Together with KYB staff we received cooperation from the customer that would be handling development with negotiations on the actual factory side that we were going to use, with product procurement, and so on ? somehow we managed to just barely get everything finished.

Commitment to performance as an engineer

We had a need while establishing our foundations during development for an electromagnetic motor. As I mentioned, it’s difficult to make new products, so where you search for these products becomes important. However, searching for products that meet our performance targets while meeting our costs was a difficult task. The motor we used this time was actually a motor for power windows on vehicles, but because our application was entirely different naturally the manufacturer wouldn’t warranty it. We started first by ensuring the motor was earthquake resistant and durable. In the end we examined whether it satisfied our requirements for performance and shape, and further whether it met our logistics costs, and after all that we were able to select this motor. For performance, what we were most particular about was whether it could be adjusted while riding the motorbike. With the motor we used for reference, you couldn’t adjust it unless you got off the motorbike once. We didn’t think people would be satisfied with this, so we thoroughly reviewed the detailed areas that would allow people to make adjustments while riding. It’s actually hydraulic, so we tried a variety of things such as adjusting the piston’s surface ratio using Pascal’s theorem and reducing loss by minimizing resistance in the mechanical mechanisms between a motor and pistons. Ultimately we were approved by the review board for mass production and finally reached our goal. It felt more like we overcame something, rather than like a sense of accomplishment. I think I’d maybe feel a sense of accomplishment when motorbikes equipped with this motor are released and actually available, and I see one for myself.

Just doing what you’re told is boring.

I think KYB is an open company. If employees make good on their word as they work, then no one will stop them when they say that they want to do something. However, naturally there are things that you have to do as part of your job. Even though I joined KYB because I love cars, motorbikes, and manufacturing, it would be boring if I just did what I was told. When I’m mentoring younger employees, I want young people to be assertive in a good way and to have the backbone to create their ideal thing or change the existing system while doing the work that they’ve been assigned. I also expect them to develop and release products that will usher in the next generation.