- HOME>

- Corporate Information>

- KYB’s Sustainability>

- Environment>

- Activity Achievements

Activity Achievements

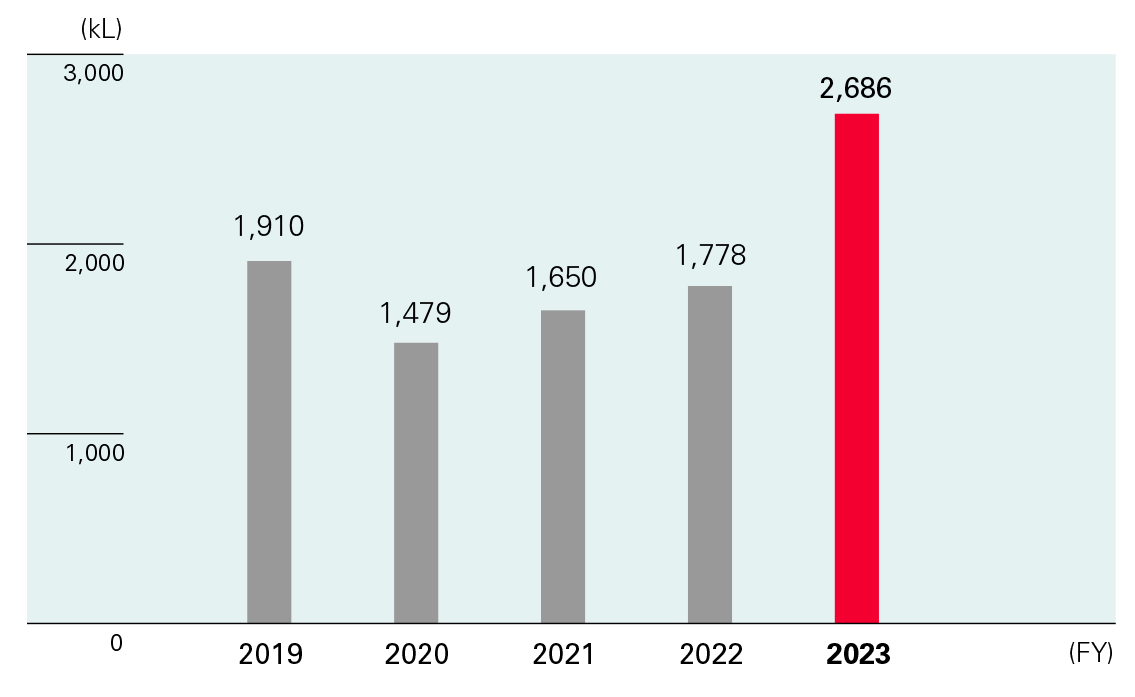

FY2023 Activity Achievements

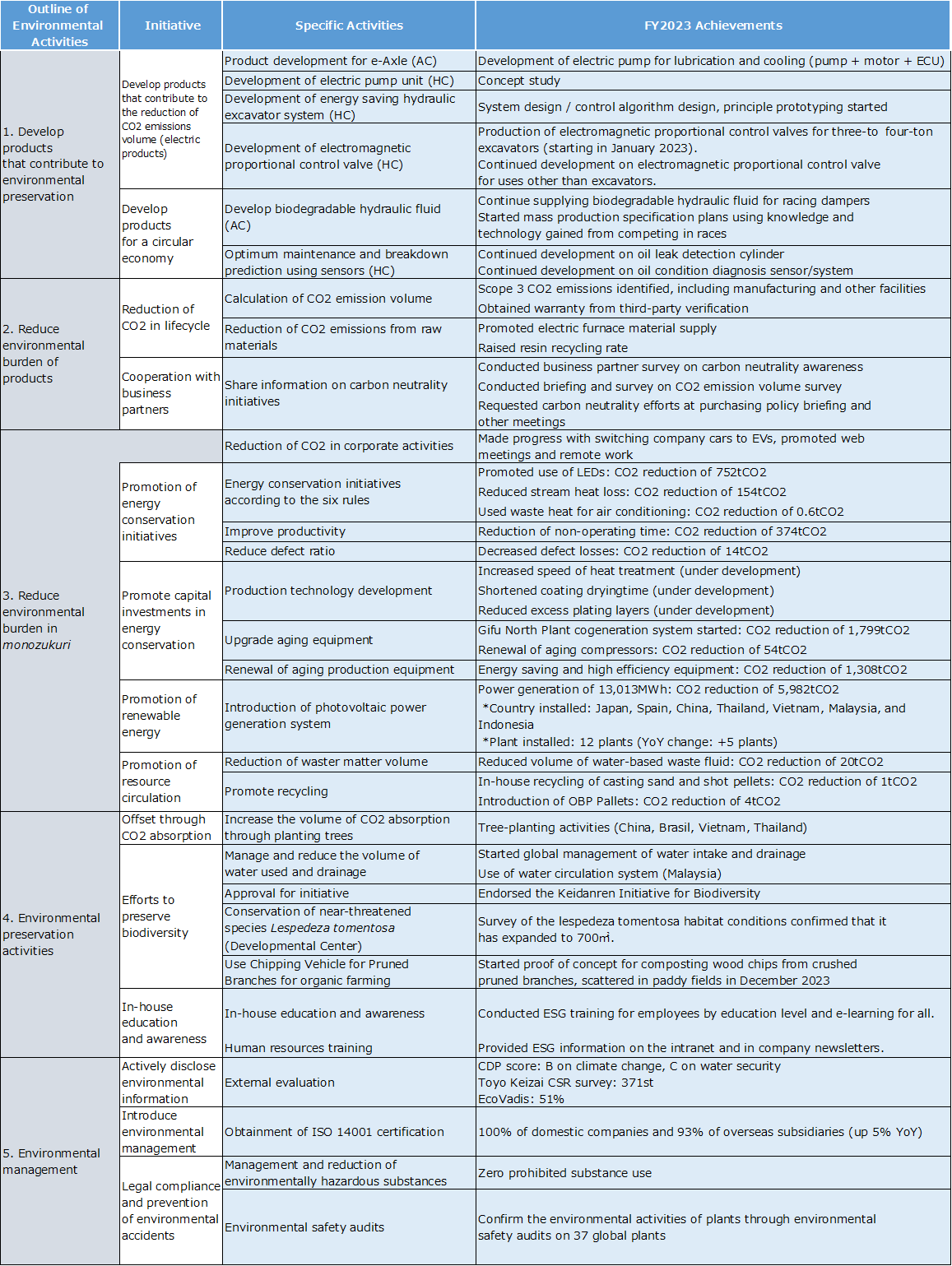

Evaluation of FY2023 Activities

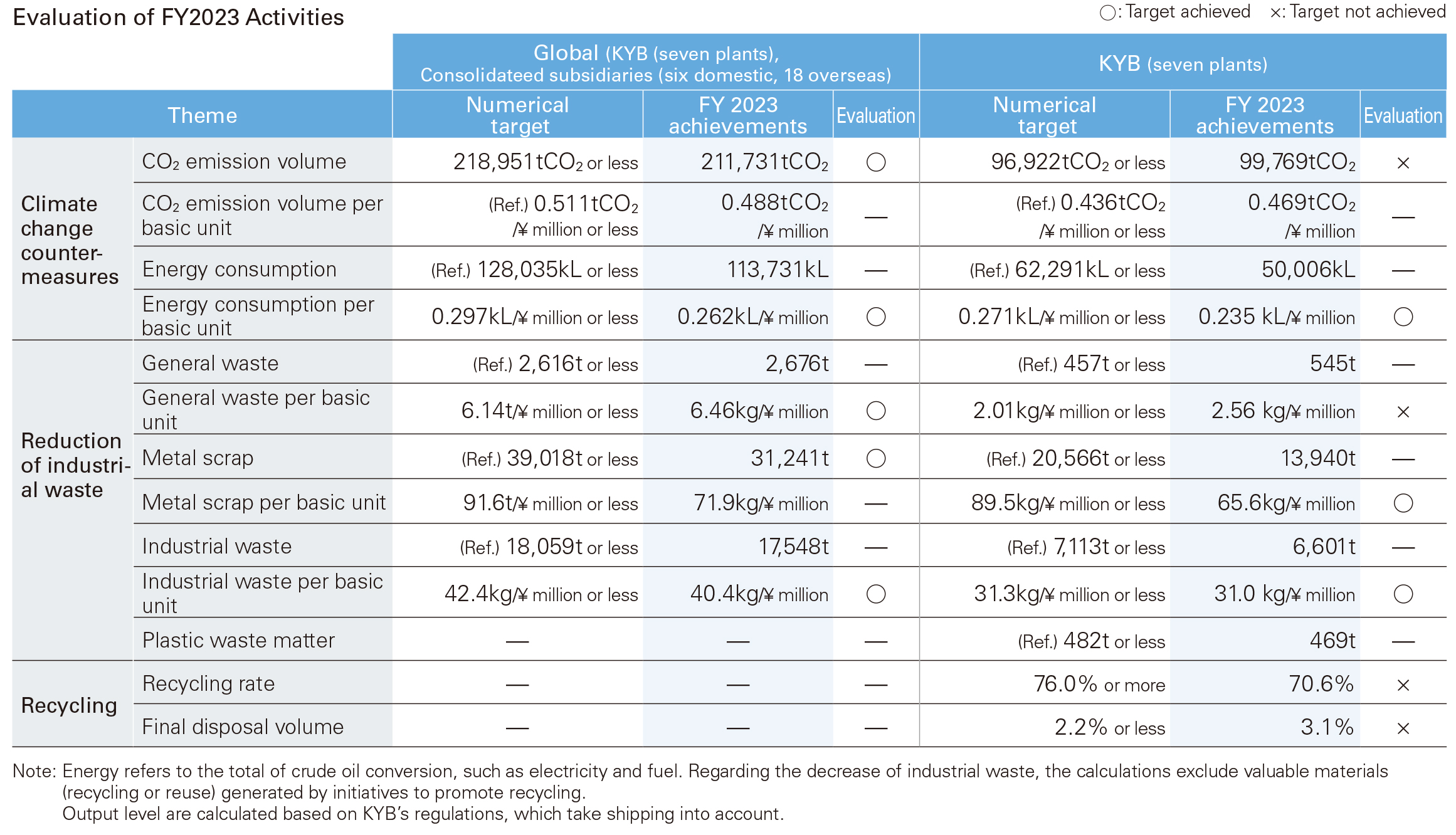

Energy Consumption

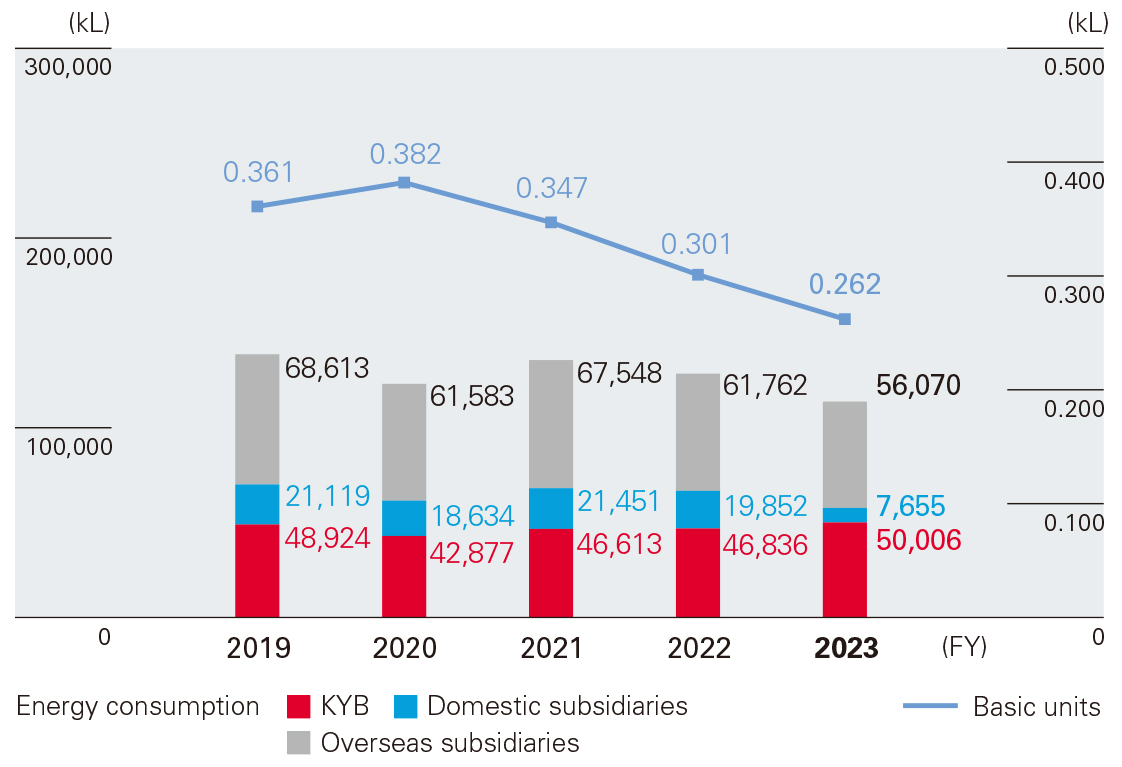

Energy Consumption for Transportation

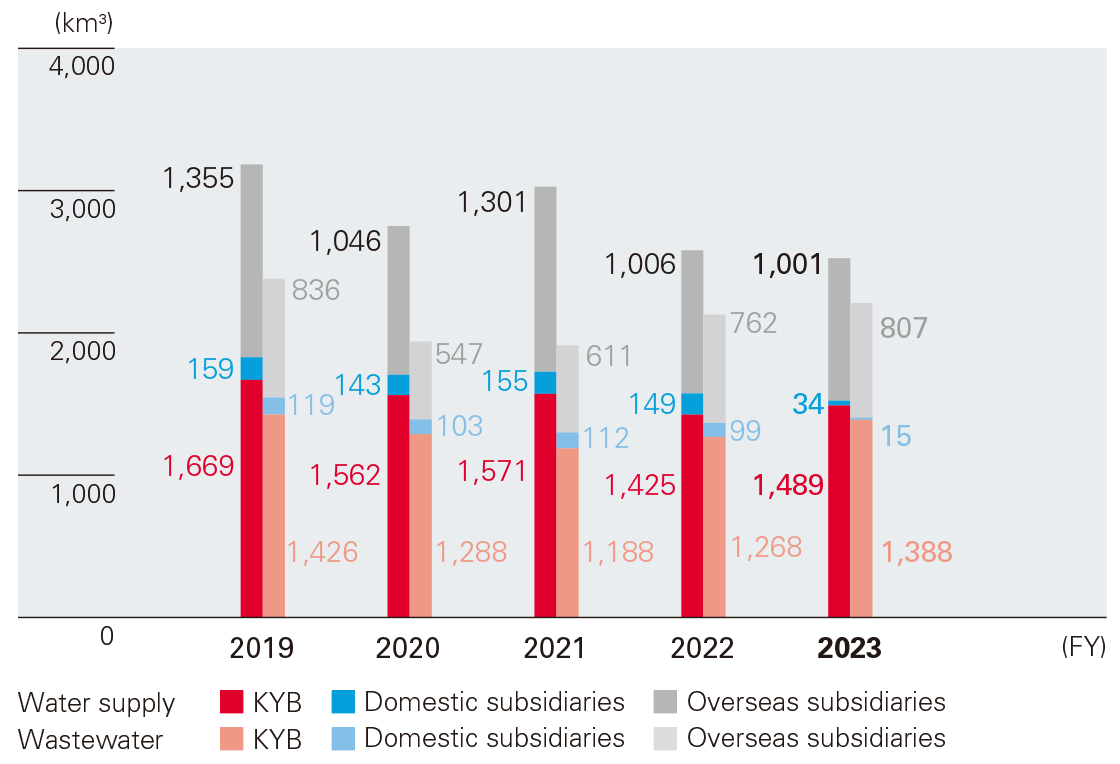

Water Usage

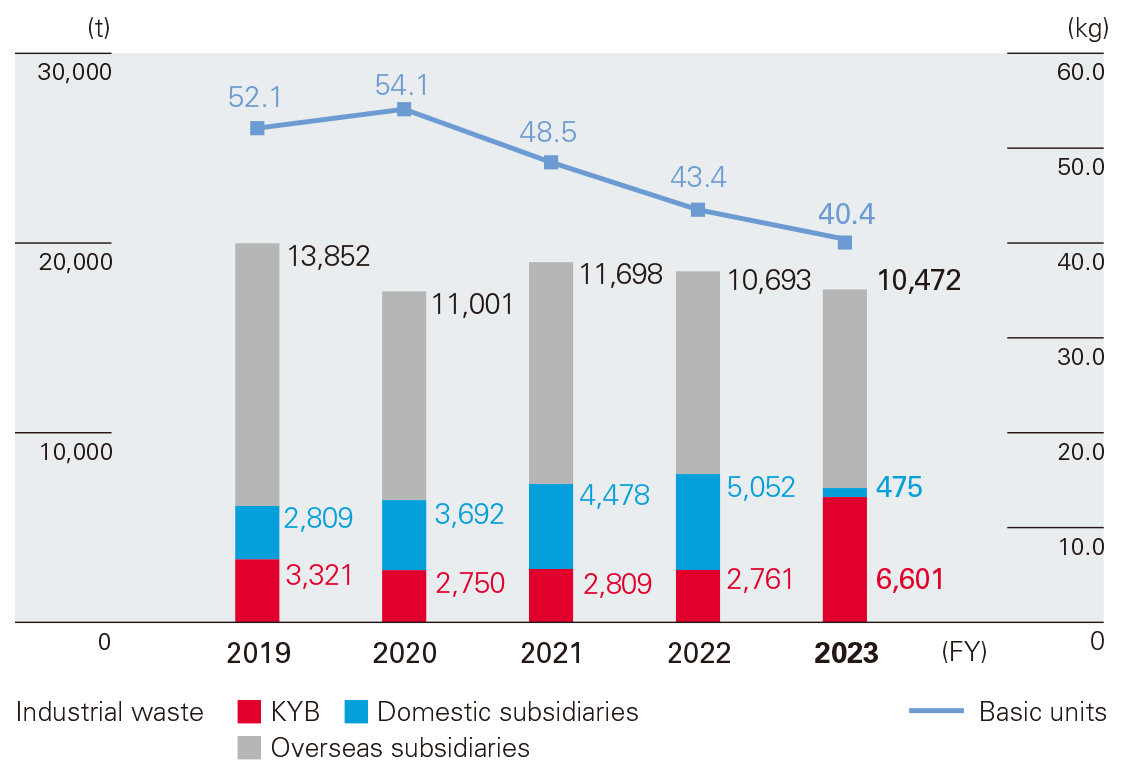

Industrial waste: Volume treated by contractors

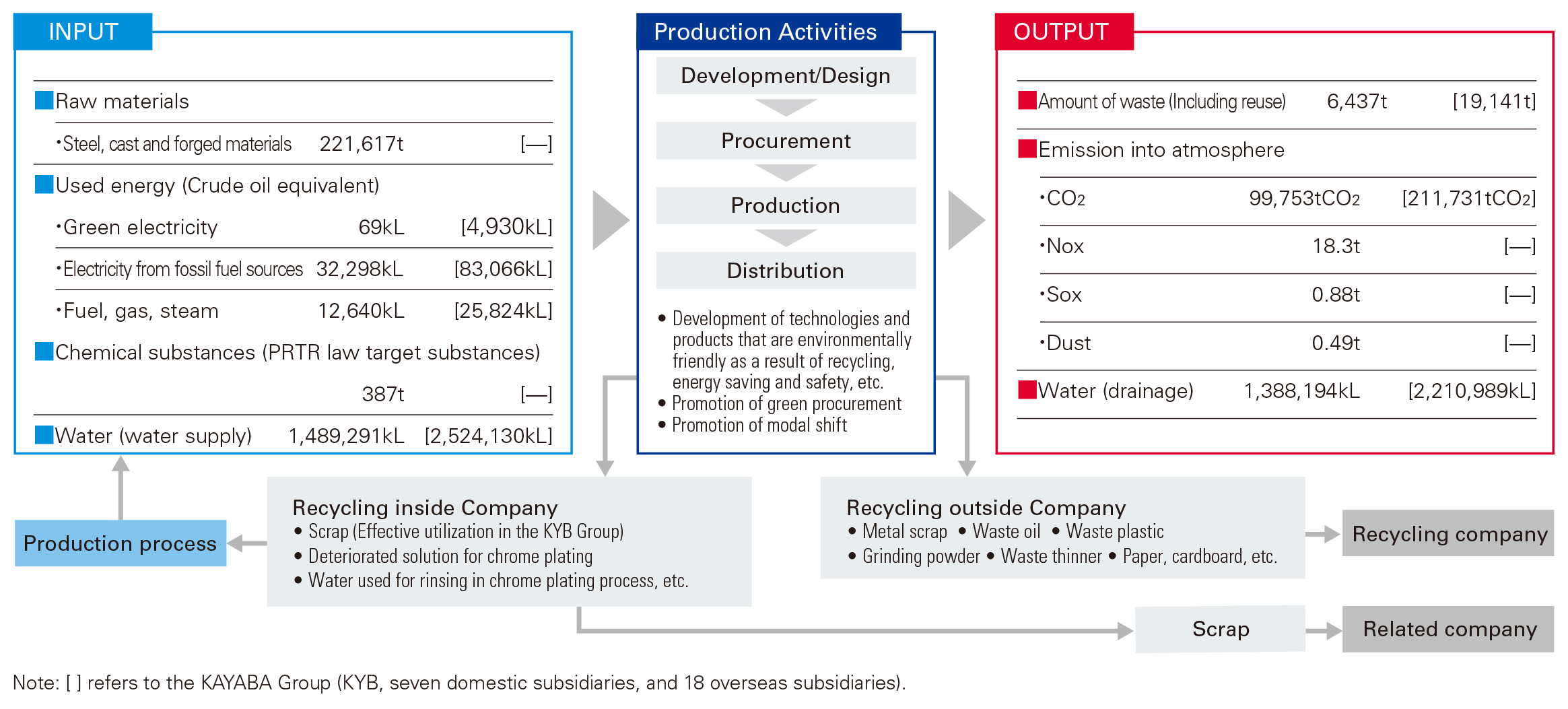

Resource Circulation and Consideration of Environmental Burden

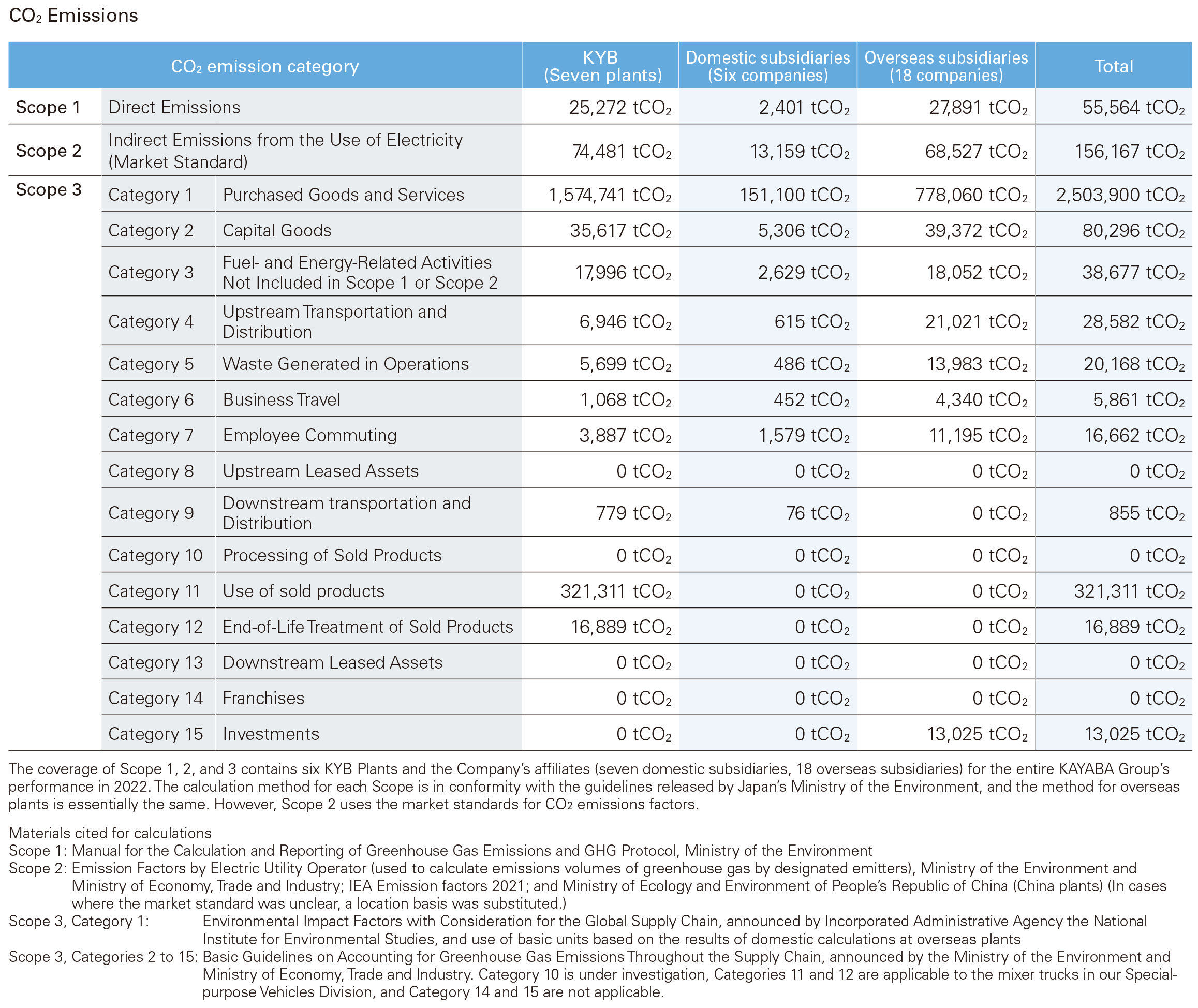

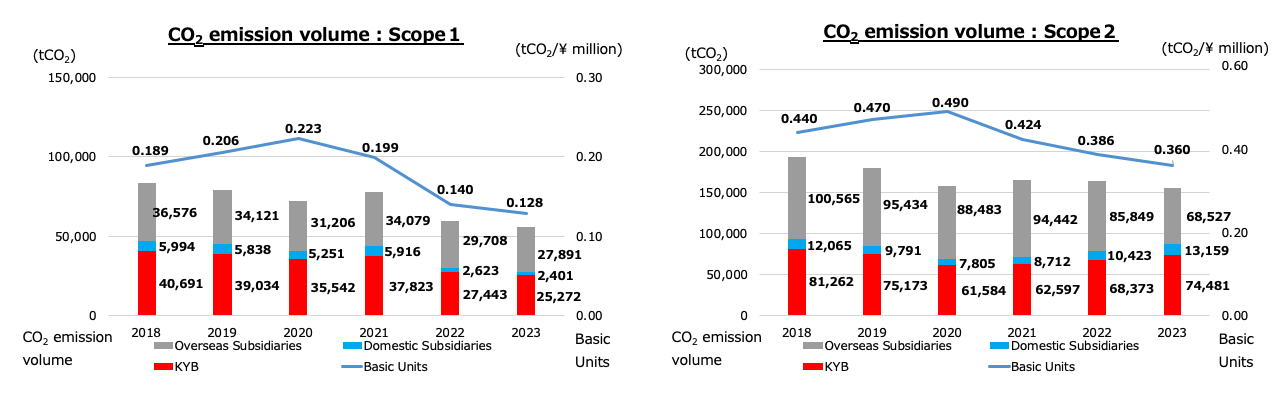

CO2 Emissions

Examples of Our Efforts

(1) Installation of Solar Power Generation Systems (Introduction of Renewable Energy)

In China, Thailand, Vietnam, Malaysia, and Indonesia, solar panels were newly installed on the roofs of factories, and all the electricity generated at those factories was consumed. This led to a CO2 emission reduction of 5,982tCO2 in FY2023.

(2) Purchase of carbon neutral city gas (introduction of green energy)

Carbon neutral city gas reduces CO2 emissions by carbon offsetting the CO2 generated in the process from mining to combustion of natural gas with CO2 credits*.

The Gifu North Plant has been supplied with this city gas by Toho Gas since March 2022, and the CO2 emission reduction effect in fiscal 2023 was equivalent to 3,135 tCO2/year. Since this city gas has not been officially certified, the amount of CO2 emission offset (Scope 1) has not been recorded, but we will contribute to the realization of a carbon neutral society.

*CO2 credits: Certificates that allow gas production and transportation to offset CO2 emissions, certified by a verifying organization for CO2 reduction effects of environmental conservation projects around the world.

(3) Renewal of cogeneration system

The gas turbine type cogeneration system at the Gifu North Plant was replaced with a high-efficiency gas engine type due to its age (in operation since January 2024). This will reduce fuel and electricity consumption, and is expected to lead to a reduction of 2,521 tCO2 per year in Scope 1 and 4,671 tCO2 per year in Scope 2, resulting in a reduction of 1,791 tCO2 in FY2023. This system is also effective as a BCP measure as an emergency power source within the plant, and the gas company will be able to remotely monitor the operation status to ensure a reliable energy supply.

(4) Installation of high-efficiency compressors

Of the seven compressors that account for 28% of the Kumagaya Plant's CO2 emissions, three (one electric and two heavy oil) were removed due to aging, and one electric compressor was replaced with an energy-saving compressor, and two heavy oil compressors were replaced with one electric compressor (the latest inverter controlled type), resulting in a 54 tCO2 reduction annually.

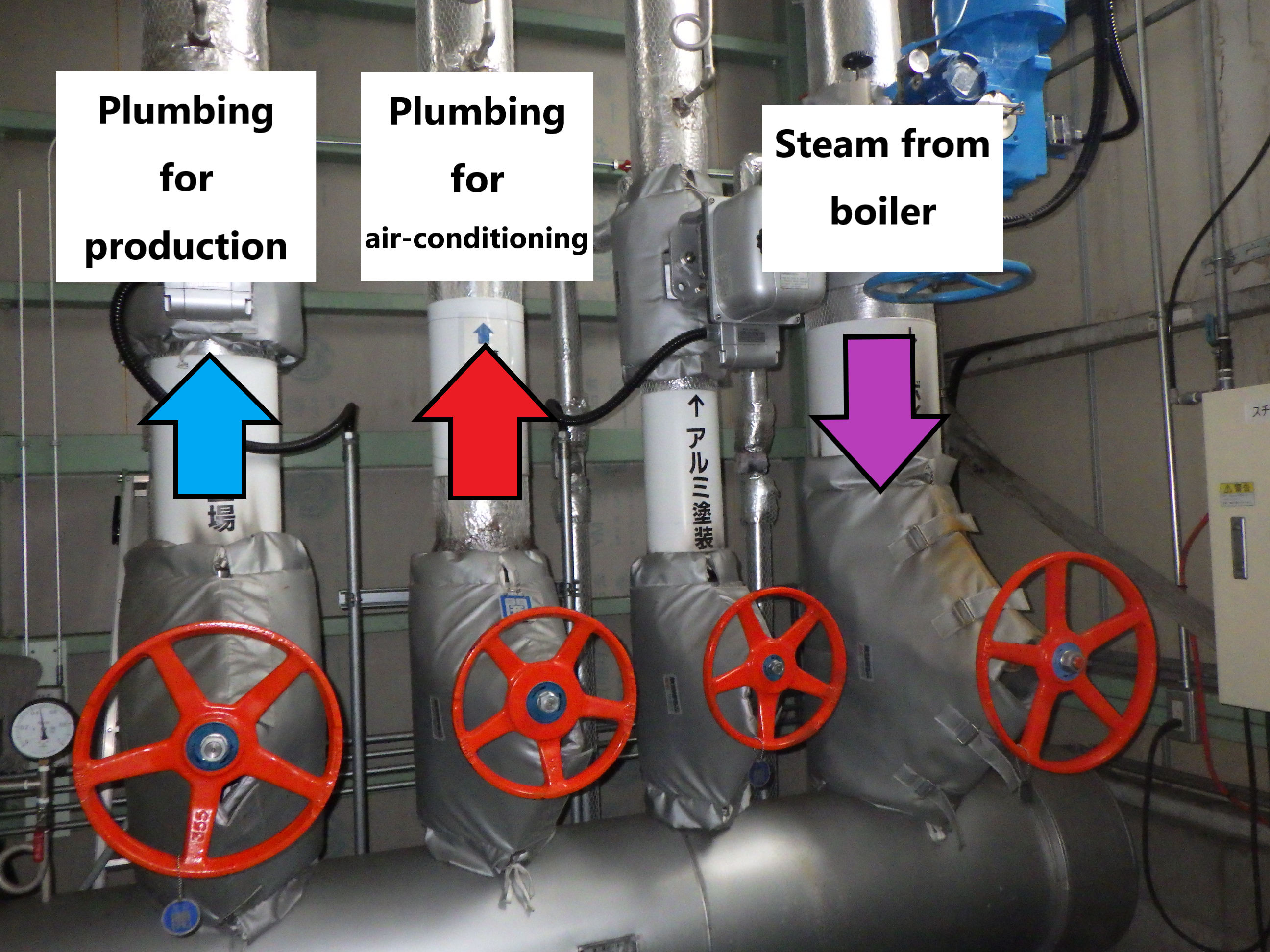

(5) Reduction of steam heat loss by system separation

The piping system was reviewed and completely separated because of the complicated mixing of heating and production piping. The valve of the heating piping can be closed in the summer when heating is not required, which has reduced the heat loss from the heating piping and led to a reduction in CO2 emissions (154 tCO2/year).

(6) Started introducing OBP pallets

The Gifu North Plant has begun to introduce pallets made partly from Ocean Bound Plastic (OBP) for transportation and storage, which can reduce CO2 emissions by 80% compared to conventional plastic pallets. (4 tCO2 reduction in FY2023)

OBP is a plastic that is disposed of inland within about 50 km from the coast and can be discharged into the ocean; active use of OBP pallets will help prevent ocean pollution caused by marine plastics. We will continue our efforts to protect the global environment by utilizing earth-friendly OBP materials.

(7) Tree Planting Activities

We participated in local events and took part in tree planting activities in public areas (China, Thailand, Brazil, Vietnam). We promote a high level of environmental awareness among employees.